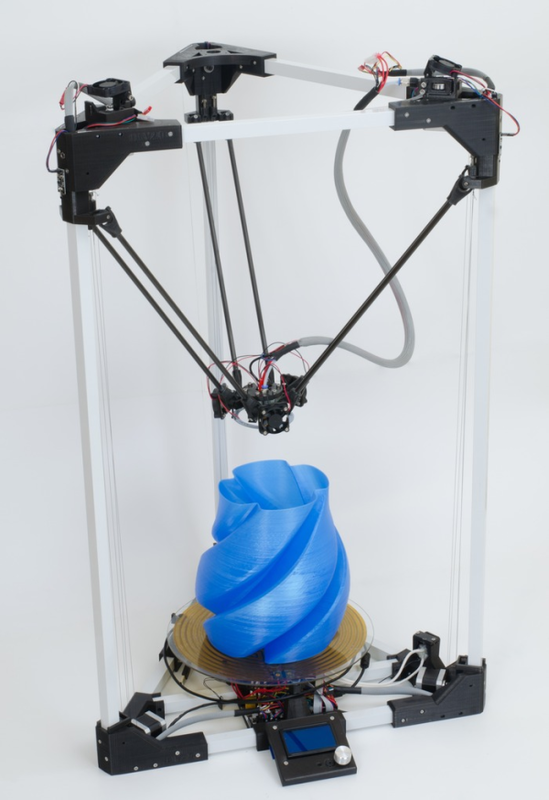

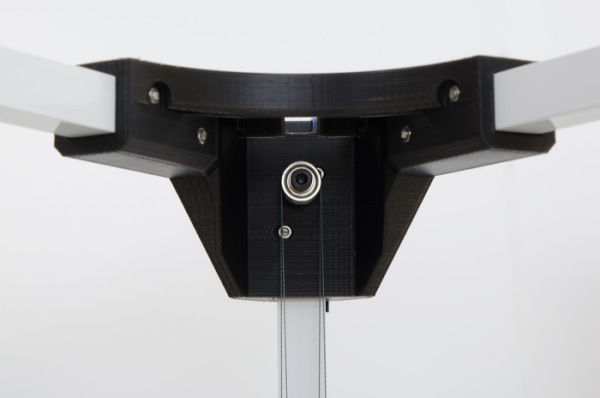

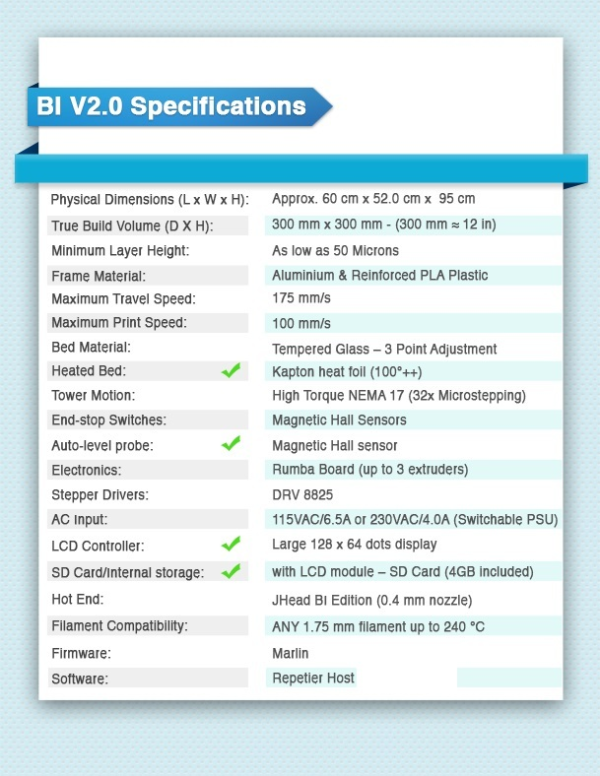

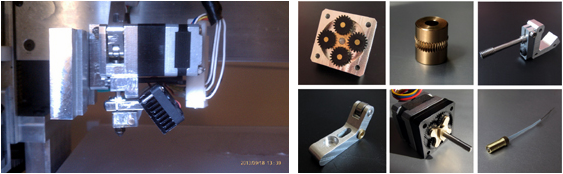

Quebec, Canada based Bootsindustries launched the BI V2.0 today , a self-replicating, high precision, Delta 3D printer on KickStarter. The structure of the BI V2.0 is made of steel reinforced 3D printed corners and 3/4 inch anodized aluminium extrusions. It uses a triple pulley system which automatically keeps the delta arms of each tower level to ensure a high precision motion. BI V2.0 features very large build volume - it is capable to produce 300 mm diameter X 300 mm height prints. The self-replicating design empowers you to create another machine and share with others. It also includes a redesigned 0.4 mm JHead for the extruder hot end called the Jhead BI Edition. This design doesn't allow backflow allowing you to print high speeds without clogging.

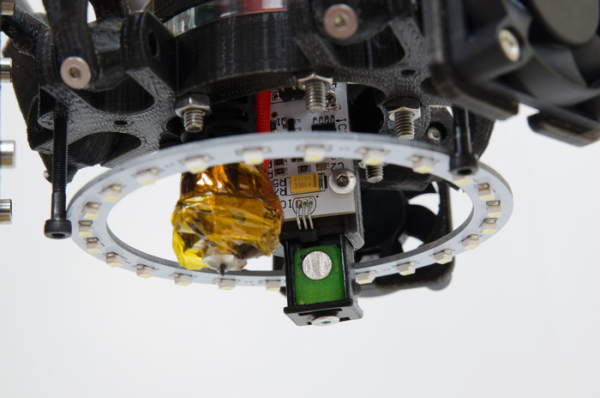

Another critical feature of BI V2.0 is an auto-level probe which could measure the height of your print bed at various points and automatically adjust the height of the print nozzle depending on current location. The result is a consistent layering across the large 300 mm diameter.

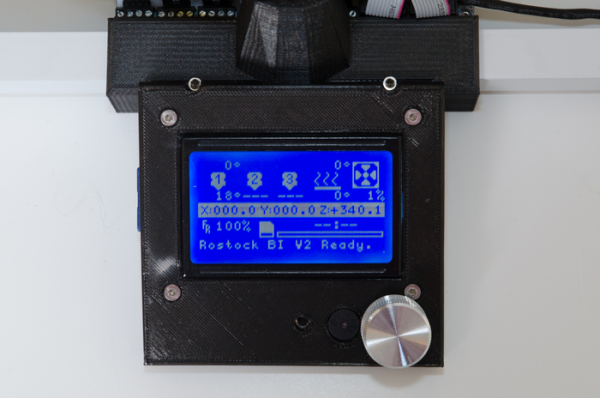

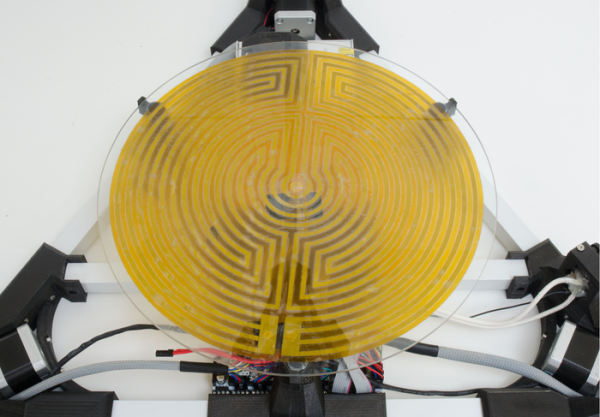

BI V2.0 can be controlled through a LCD controller with large screen. The user has the ability to move the printer, set speeds, temperatures and start prints when their G Code is stored on the SD Card. The Bi V2.0 comes standard with the LCD controller and a 4 GB SD card. The delta platform is built with carbon fibre rods, 3D printed PLA, a laser cut acrylic tooling insert and has a capacity of up to three hot ends. All BI V2.0 3D printers will ship out with a heat bed, comprising a heat foil, glass and a magnetic fastening system. The BI V2.0 is capable of producing high quality prints in either PLA, ABS, Nylon with 50 micron layer height. Additional features of the BI V2.0 include: - Sleeved electrical wiring for a clean look.

- Quick disconnect wires in the most convenient places to facilitate maintenance and reconfiguration.

- Triple fan assembly to maintain consistent temperatures.

- Powerful LED ring to see the printer in action.

Bootsindustries released BI V2.0 today on Kickstarter and in few hours the limited Early Bird Special offers were all gone. The cheapest option available now is an Early Adopter Special: for 685CAD (USD644 / EUR471) you can get your BI V2.0 3D Printer complete with heat bed, LCD controller and Auto-level probe. Shipping cost not included.

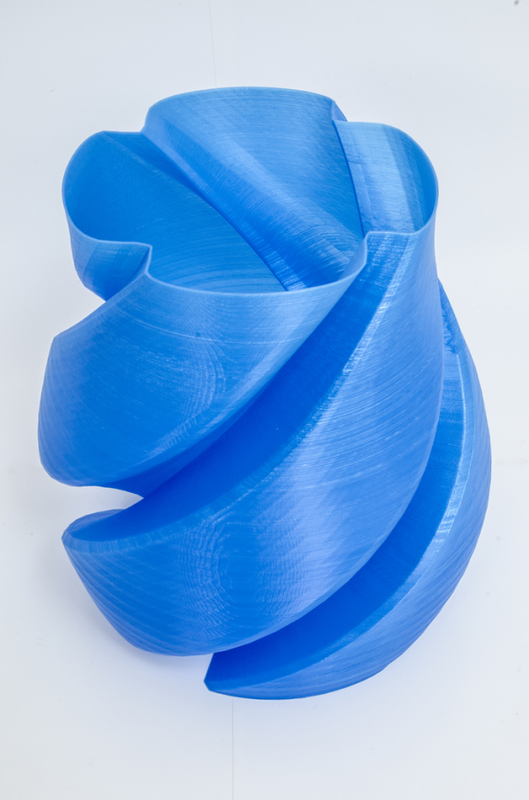

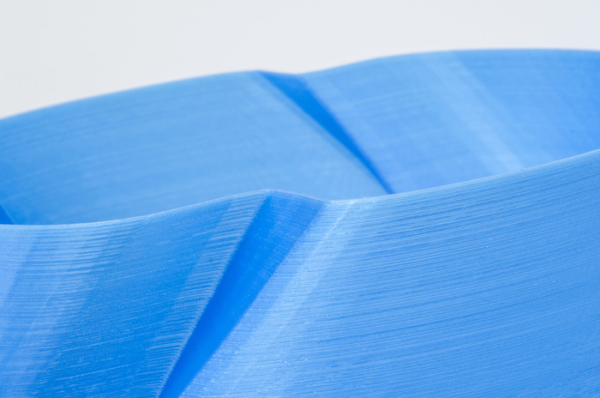

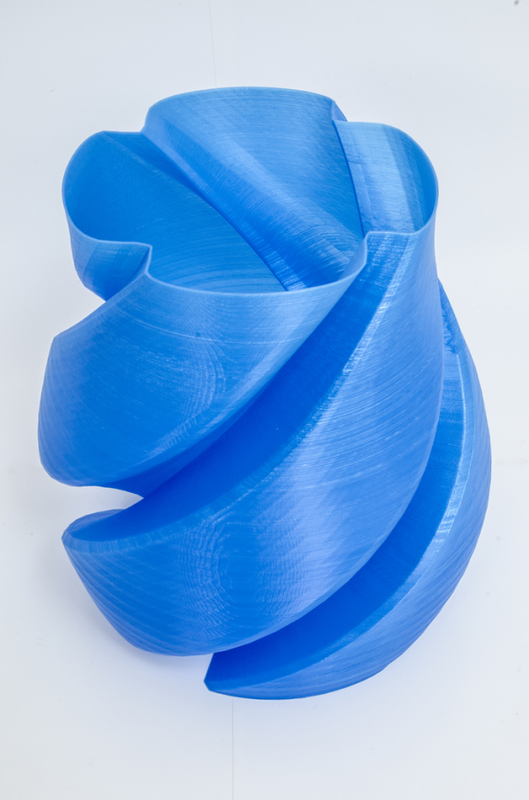

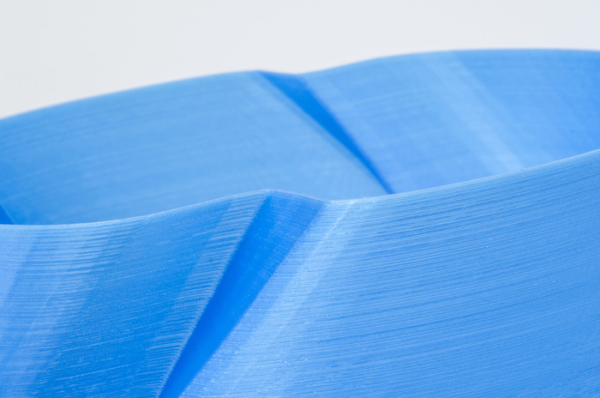

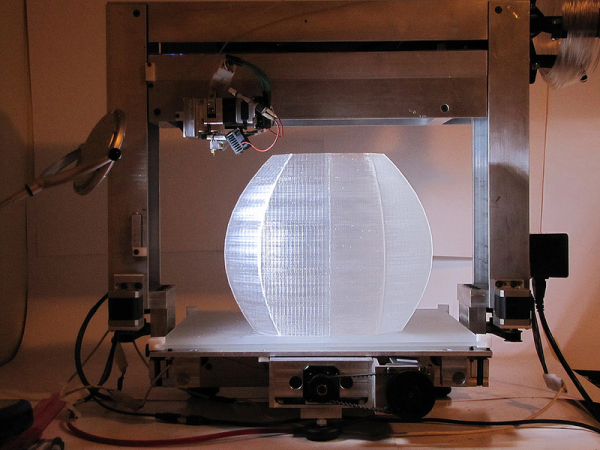

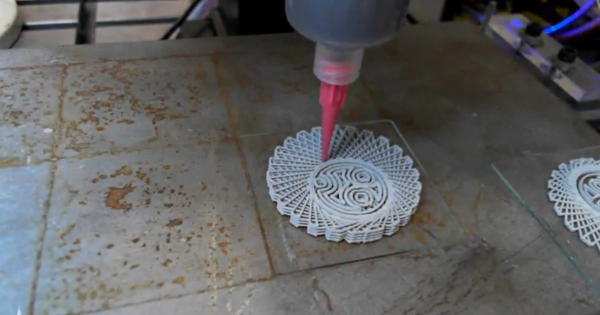

Propellor vase by jameswood - Scaled up to a height of 250 mm

High quality setting - 0.22 mm @ 2400 mm/min

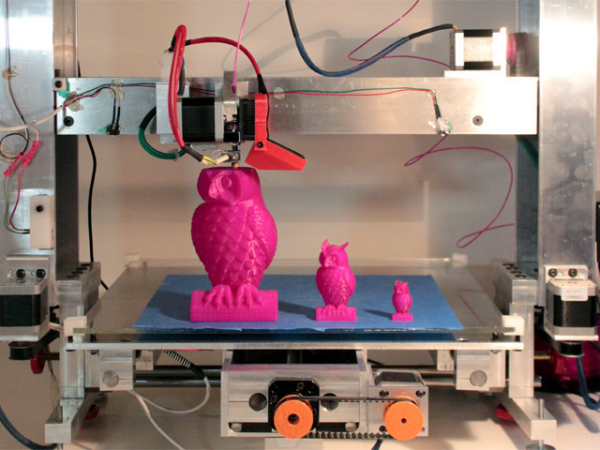

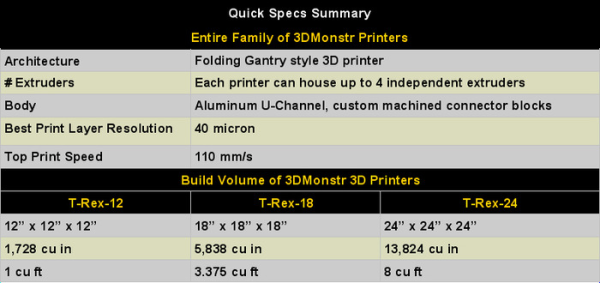

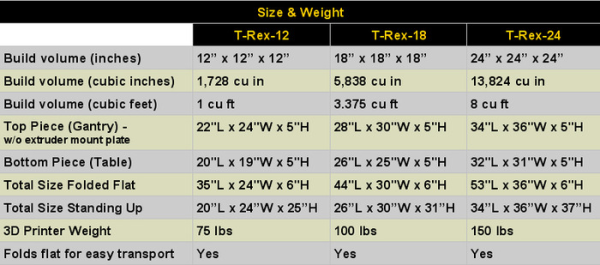

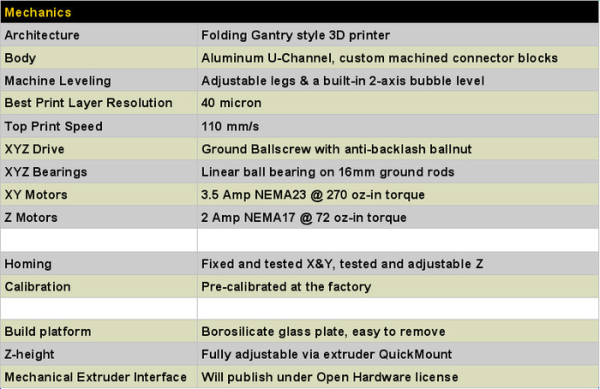

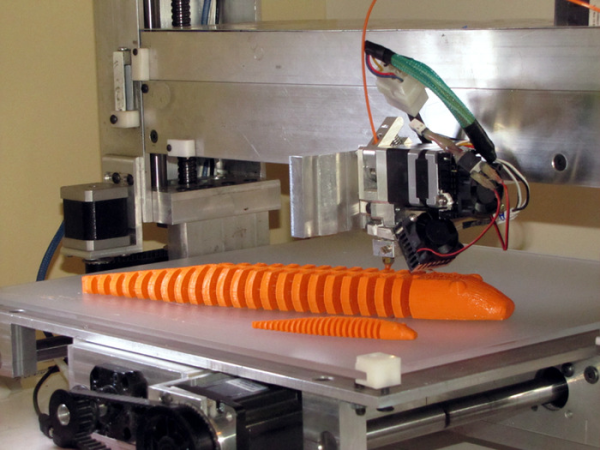

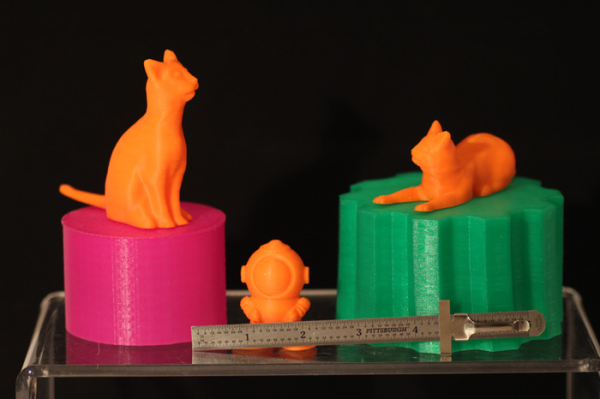

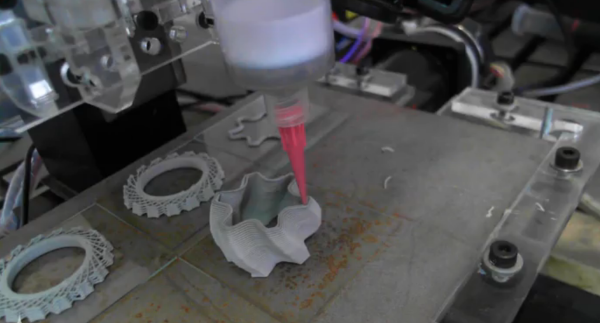

You can now print large, complex objects in multiple materials with precision and enough speed on 3DMonstr. 3DMonstr is a rigid and powerful 3D printer with large build volume. The smallest of its family is 1 cubic foot and the largest is 8 cubic feet. 3DMonstr printers come in two parts, the gantry and the table bed for easy transport. Its openwork frame is built from high strength U-channel extrusions, providing the necessary rigidity. The printers can be folded for storage and transport. The specially designed self-aligning locking mechanism enables makers to repeatedly lock and unlock the printer into a horizontal position for easy transport. A level is built into the frame, so that the printer can be easily used on uneven surfaces simply by turning the leveling feet. The heated printbed is made from 1/4" aircraft grade aluminum plate and the print surface is borosilicate glass. Its extruder is designed specially for 3DMonstr printers which , according to the team, is almost .5" smaller in width than most of the extruders out there and weighs about half. Each printer can house up to 4 extruders, each with its own temperature control. More than one extruder will enable makers to add a temporary support material, add additional colors, or additional materials. "When the printer is fully populated with four extruders, you may use one material extruded through a fine nozzle for the perimeter, a larger diameter nozzle for the infill, an easily dissolved plastic for support scaffolding, and another material for special purposes (such as a different perimeter color or electrically conductive structures printed right in)." writes the team. The extruders are attached to the machine via a QuickMount release making it really easy to switch them in and out. Future extruders will include 'Food grade' for chocolate, frosting, cheese, 'Low-temp paste' for paraffin wax, silicon rubber, clay, and ceramics, and 'Plastic pellets' for ABS and PLA. The 3DMonstr printer family has three models: - T-Rex-12: The one cubic foot model, provides a 12"x12x12" (304 x 304 x 304 mm) build platform.

- T-Rex-18: The 3.375 cubic feet (5,832 cubic inches) model, provides an 18"x18x18" (457 x 457 x 457 mm) build platform.

- T-Rex-24: The 8 cubic feet model, provides a 24"x24x24" (610 x 610 x 610 mm) build platform.

3DMonstr printers are capable of printing 40 micron layers with max. print speed of 110mm/s. It supports PLA, HIPS, PVA & Nylon. Check out the specs for 3DMonstr below: The price for 3D printers starts at $2,499. The 3DMonstr team has launched 3DMonstr 3D printers on Kickstarter. Check them out here.

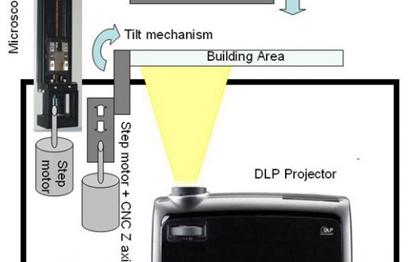

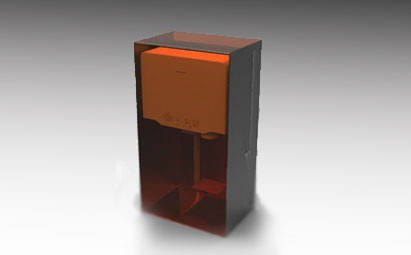

Typical 3D printers use a process called fused deposition modeling (FDM), in which a nozzle extrudes melted plastic filament, laying down material in layers. Traditional stereolithography uses a scanning UV laser to cure a liquid, called photosensitive resin, one layer at a time. A DLP printer is similar, but uses a a Digital Light Processing (DLP) projector to expose each layer. Once the first layer hardens onto a platform, the platform moves a little deeper into the pool of resin, and the projector shines a new image to harden the next layer. Taiwanese company Nova 3D has recently developed a new low-cost DLP 3D printer. The NOVA DLP 3D Printer is able to harden a layer of 10x8 cm in 8-10 seconds without the typical moving heads that takes 30 seconds or more to finish. The big benefit of DLP printing is the ability to make objects very detailed. The NOVA DLP 3D Printer can print layer heights of 100 microns (0.0039 inches). Check out some impressive 3D prints below: Technical specs: - Build envelope: 100x70x150 mm (0.1mm precision)

- XY precision: 0.1mm

- Z precision: 0.1mm

- Software: Snapshot version 1.0

- File print: STL

- Machine size: 212x310x600 mm

- Weight: 12kg

- Operating temperature: 0°-32° C

- AC input: 100-240V,~2A,50-60HZ

- Data input: USB

The NOVA DLP Desktop 3D printer is available for $999 at NOVA 3D's online store.

UK based Newton 3D today unveiled some information about its ground breaking desktop metal 3D printer. Built from the research of Esteban Schunemann, PhD student at Brunel University in London, Newton 3D is claimed to be an affordable 3D printer that can 3D print objects in metals such as gold, silver, bronze, copper and steel. It was developed specifically for jewellers, product designers, homeware designers and fashion designers. Newton 3D was founded in 2009 by Esteban Schunemann and was funded by iMakr.VC. Esteban's design was awarded the joint winner prize for the Goldsmiths' Technological Innovation Award 2013 by the Craft and Design Council. The Newton 3D uses metal clays such as bronze, sterling silver, copper and steel which are then fired. The parts can also be finished. According to the company, The Newton 3D has build platform around 5 in x 5 in (127 x 127 mm) but so far they have focused on applications to smaller pieces. "The system itself can move at 2000mm/min, but with metal we prefer to keep it at 300mm/min. The cufflinks take 15 min to print each." Romain Kidd, Chief Marketing Officer of iMakr.com told us. But aside from the above brief information the company gave on the product, Newton 3D has kept much of it under wraps, declining to reveal how the 3D printer looks like, what hardware and software it includes, and how much the device costs. "We will be slowly revealing more in the coming weeks." said Kidd. For our curious readers Newton 3D has shared exclusively 2 videos of the printing process, and you can find them here and here. Stay tuned for more information. Below are a few nice 3D printed metal objects made on the Newton 3D metal printer.

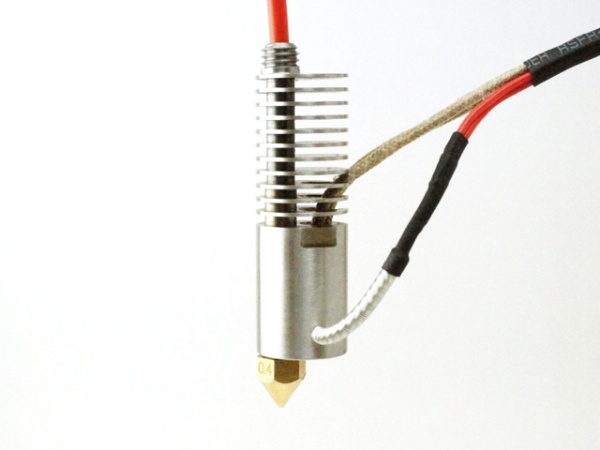

B3 Innovations quickly met and exceeded its initial fundraising goal $17,500 after only 48 hours for Pico, the company's all-metal hot-end for RepRap 3D printers. B3 co-founder Michael Koury said, "We are humbled and ecstatic at the support and response for Pico in such a short timeframe." The Pico fundraising campaign on Kickstarter still has 23 days to raise the bar, so B3 is offering a $40,000 stretch goal to develop a Pico that prints up to 500° Celsius (932° Fahrenheit), the first of its kind for the 3D printing market. This is important for some polycarbonates on the market in addition to printing materials that are on the horizon. "Filament greatly affects the finish of a 3D print", said William Moujaes, B3 Innovation's co-founder.

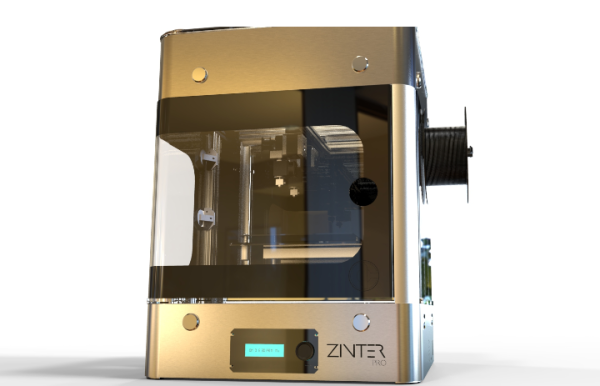

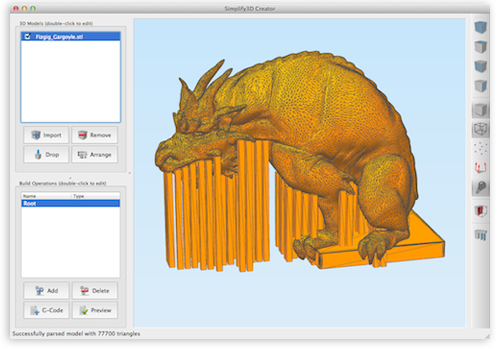

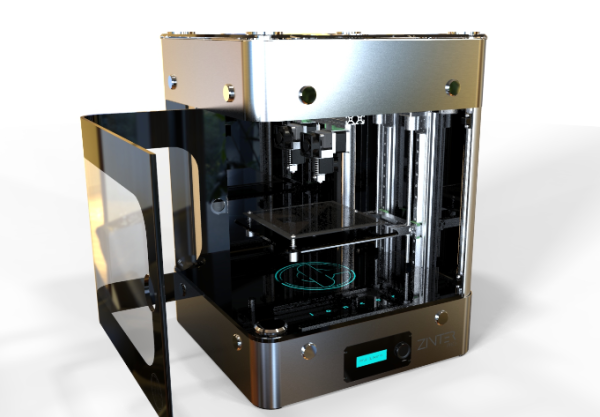

North Devon, UK based Ion Core Ltd, a new company started by James Marchant, Alexander Nall-Cain and Richard Dinan, developed a slick consumer 3D printer called Zinter PRO. The Zinter PRO features a fully enclosed build area and heated build platform which could cut down problems of warping and uneven cooling of layers since the heat is kept in the enclosure, also it will keep the print safe from disturbances while in progress. The Zinter PRO 3D printer comes with two extruders for two-coloring or two materials printing. Dual extruders really seems to be the norm lately.Also featured is the Ion Core Simplify3D Software that gives users complete control over the placement of support material. "No wasting plastic and time printing unnecessary material!" says Ion Core. What seems really cool is that they are also developing an add-in that can convert traditional 2D images into representative 3D parts. Meanwhile Ion Core is developing a free to use platform 'ZintShare' that allows users to upload and download 3D files for use with Zinter 3D printer. ZintShare will launch in February 2014. The Zinter PRO 3D printer is priced at £2,350 (€2,800 / $3,850) with 10 week lead time. Technical Specification: - Print Technology: Fused Filament Fabrication

- Build Volume: 200mm x 200mm x 200mm

- Heated Bed: Yes

- Filament Diameter: 1.75mm

- Number of Extruders: 2

- Nozzle Diameter: 2 x 0.4mm

- Print Materials: ABS, PLA, Nylon, PVA, PC

- Connectivity: Standalone SD card and USB cable

- Movement: Patented linear rails and carriages

- Chassis: Aluminium framework, stainless steel bands and plastic panelling

- Build Surface: Heat Glass

- CE Mark: Safety Tested and Approved

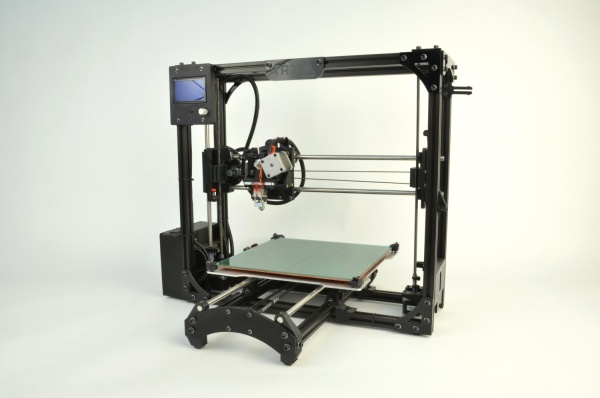

Lulzbot released today TAZ 3.0, which features injection molded parts and a redesigned 24v heat bed. That means the printer has a much faster heat time than the previous version. The TAZ 3.0 3D printer with its new design can print with more than just ABS, it can also print with PLA, PVA, high-impact polystyrene, or a wood filament. With add-ons, you can print with materials like nylon or polycarbonate! Since nylon takes such high temperatures to print correctly you must have to upgrade the hot end I would think but that's just speculation. The TAZ 3.0 now comes with a graphic LCD controller for printing directly from an SD card. The graphic LCD controller has the ability to perform print start up, print selection, and configuration changes. Printing from an SD card will make it so you don't have to worry about your computer freezingrestarting or anything! The other printing specs remain the same as the TAZ 2.0. Specifications: Printing - Print Area:298mm x 275mm x 250mm (11.7in x 10.8in x 9.8in)

- Print Volume: 20,500cm3 (1,238 in3) of usable space

- Top Print Speed: 200mm/sec (7.9in/sec)

- Layer Thickness: 0.075mm – 0.35mm (0.003in – 0.0138in)

- Usable Filament Sizes: Standard 3mm (0.1in)

Physical Dimensions - Overall Dimensions: 680mm x 520mm x 515mm (26.8in x 20.5in x 20.3in)

- Weight: 11kg (24.25lbs)

Electrical - Power Requirements: 110 – 240 VAC

Software - Marlin firmware

- Slic3r G-Code generator

- Pronterface host software

The Taz 3.0 retails for $2,195.

|

RSS Feed

RSS Feed